Testing of Railway Components

Wuppertal, Germany, August 25, 2020

Testing of Railway Components

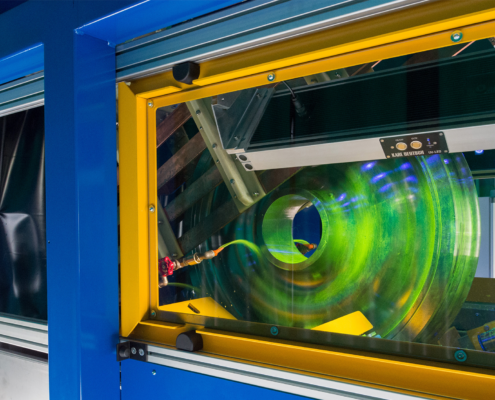

KARL DEUTSCH has an extensive experience in the development and manufacturing of testing equipment and systems for railway components: For railway wheels and tires, a DEUTROMAT system is preferably used. The so-called Minden coil is used for the magnetization of the wheels and for the magnetization of the wheel tires a high-current hinged coil with adjusted yokes. In order to be able to examine the entire surface, a complete rotation of the test part is necessary. KARL DEUTSCH also offers the right solution for the testing of axle shafts that are either as-manufactured or inspected in the context of a revision.