ScanMaster UT/X: “Arplas Weld” testing

Wuppertal, Germany, 12 August 2022

ScanMaster UT/X: “Arplas Weld” testing

In addition to the most widespread resistance spot welding, there are numerous other methods for making joints in car body construction. These joints are produced by stamping, soldering, glueing or other methods.

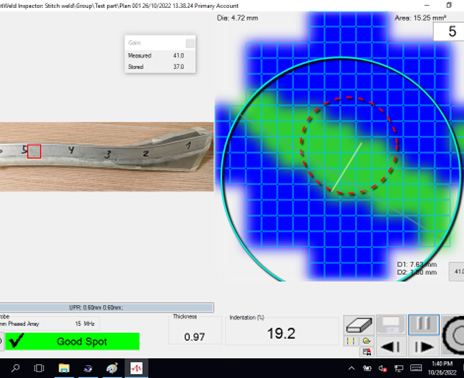

There are also special seam types within the scope of resistance welding that require modified testing algorithms with respect to established testing with ultrasound. Weld seams produced with the so-called “Arplas Method” are becoming increasingly popular. These seams are characterised by a lower indentation depth and are almost invisible when painted. However, they are not round but elongated, and the inner structure is different from “normal” spot welds. A special algorithm in the UT/X phased array system now makes it possible to display this type of weld seam and automatically measures the relevant parameters. As with “conventional” spot welds, an automatic evaluation of the weld is carried out.