ScanMaster UT/X: Measuring Large Spotweld Diameters

Wuppertal, Germany, 21 February 2022

Probes for Wall Thickness Measurement

In contrast to spot weld inspection by means of conventional ultrasound, the phased array based UT/X not only allows different-sized spots to be inspected but also measurement with a single probe.

With conventional testing, a nominal welding lens diameter is compared with the defined sonic beam diameter of the probe.

Different probes must be used for different lens diameters. Measurement of the spot does not take place.

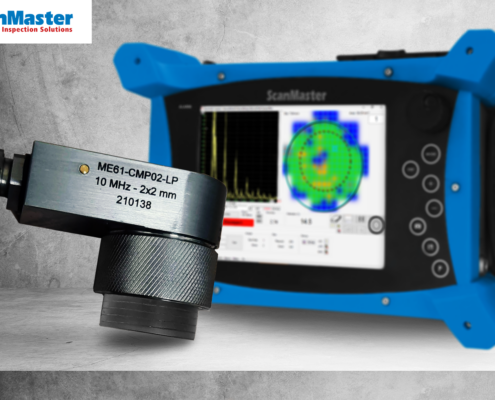

With PA-based testing, 61 elements are arranged in the probe in the form of a matrix, allowing to measure spotwelds with a diameter of up to 9 mm.

For many aluminium sheet joints, weld spots with considerably larger diameters also occur. A probe with larger individual elements and a diameter of 16 mm was developed for this purpose. Of course, either a fixed delay line (Plexiglas) or a flexible coupling surface (membrane with water column) can be used.