Railway Wheel Inspection System

Wuppertal, Germany, 01 June 2023

Railway Wheel Inspection System

Unique combined testing system for testing of forged railway wheels using multiple NDT techniques: ECHOGRAPH TTPS PAUT and DEUTROMAT with a Minden Coil

In summer 2023, the system will be integrated into a new manufacturing line on site in India, incl. automated part handling by means of a portal and robots for UT-testing of a web (in addition to standard testing functions on hubs, treads and rims). Due to an improved and standardized design costs and risks are reduced, while fully complying with the Indian standard IRS R 19-93 Part II, being even more strict than the common railway wheel standard ISO 5948. The wheels have a diameter range of 700 to 1250 mm and a maximum weight of 1000 kg.

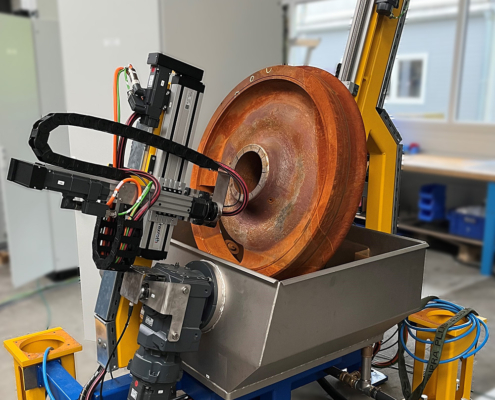

Ultrasonic Testing (UT)

The hubs (3 x FBH 3.0 mm), treads and rims (each, FBH 1.0 mm) are inspected with PAUT (2 probes 128E + 2 probes 64E) and the webs (10 x FBH 3.0) use our ECHOGRAPH 1170 conventional UT electronics and two single-element probes. The challenging defects in the radius area of the treads are successfully detected by using advanced phased array sector scans. During the inspection, the A-scans of each probe are shown on a PC, and a line chart is recorded for documentation. Optionally, a C-scan view is also possible. The UT testing cycle for the largest diameter is below 60 s (excl. robotics).

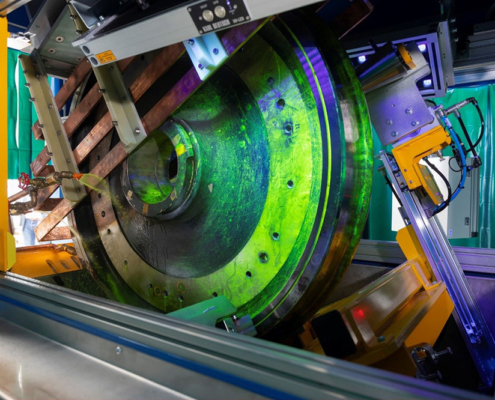

Magnetic Particle Testing (MT)

The MPI system DEUTROMAT for fluorescent inspection utilizes the Minden coil, being safely parked above the testing position during the loading of the wheel by means of a loading cart, which is suitable for the entire range of wheels. The loading cart communicates with an upper-level system and automatically travels between the testing position and the gantry loading position. Defect evaluation is carried out by an operator through the protection glass from different sides. If necessary, the operator can access the testing area via a safety door. The MPI testing cycle uses a Minden coil (incl. demagnetization), requires 1.5 turns of the wheel, which takes less than 2 min for maximum diameter at recommended rotation speed.

KARL DEUTSCH is proud to be the only manufacturer to offer this complete testing solution with development, assembly and testing taking place under one roof and based on several NDT processes at the same time.

At a glance:

- 2 non-destructive testing techniques in 1 system

- Wheel diameter: 700 to 1250 mm

- Wheel weight: 1000 kg max.

- Duration of UT: < 60 s

- Duration of MT: < 2 min (for 1.5 wheel turns and demagnetization)

- Complies with IRS R 19-93 Part II (India) which is even more challenging than the common ISO 5948