DEUTROFLUX and DEUTROMAT

Magnetic particle crack detection on railroad components

Product Description

KARL DEUTSCH has extensive expert knowledge in testing equipment and systems for railroad components.

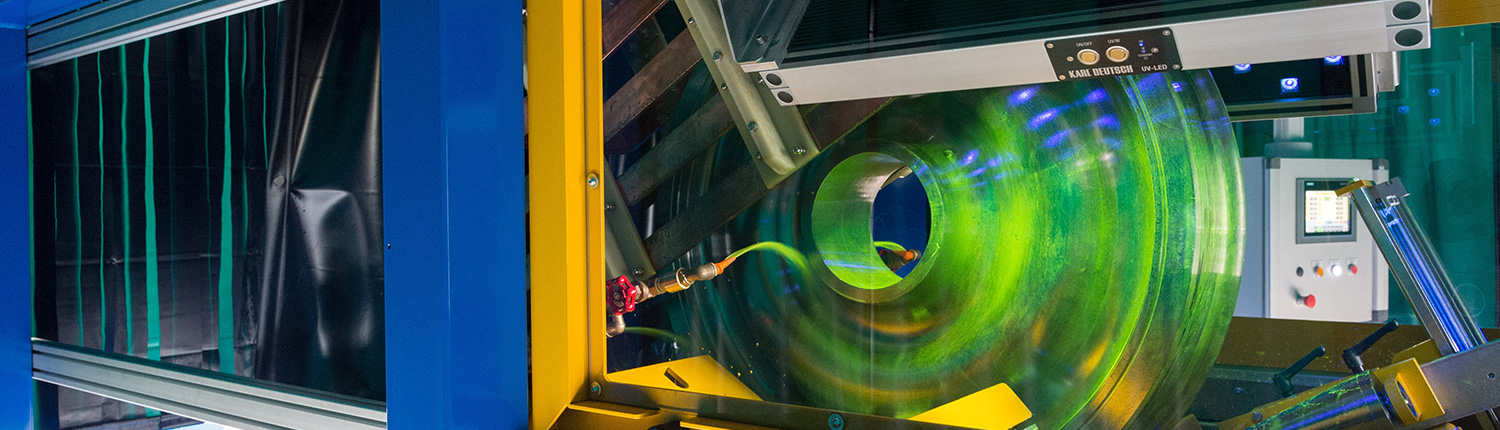

The DEUTROFLUX UWS crack testing machine is available for axle shafts that are newly manufactured or revision-tested. For railroad wheels and wheel rims a DEUTROMAT system is preferably used. A high current coil is used to magnetize the wheels. The component is completely rotated once during the test to cover the entire surface.

Purchasing a testing machine is not economically reasonable in all cases. Hand yoke and current generator (type DEUTROPULS) as well as penetrant testing (type KD-Check) may be sufficient for the test task.

Key Facts

- DEUTROFLUX UWS:

Check for longitudinal defects (in axial direction) by means of a ring field magnetization from a current flow.

Check for transverse defects (in circumferential direction) using a motor-driven moving coil with a ring shower activated on the front. For reasons of cycle time, the coil can move in both directions, wetting and magnetizing. - DEUTROMAT:

Testing of all crack directions by combination of coil and yoke - DEUTROPULS:

Mobile testing by hand yoke and current generator - KD-CHECK:

Penetrant testing - The well-proven loading by crane is used for heavy parts

Versions

Extension options:

- Automatic clamping length adjustment

- Testing of wheel set axles with wheels in place by means of a DEUTROMAT system: With a special high current coil the wheel test is then performed separately

Further Information

Our comprehensive brochure:

Things to know and accessories: