CRACKVIEW AI – AI-based evaluation of MT indications

Product Description

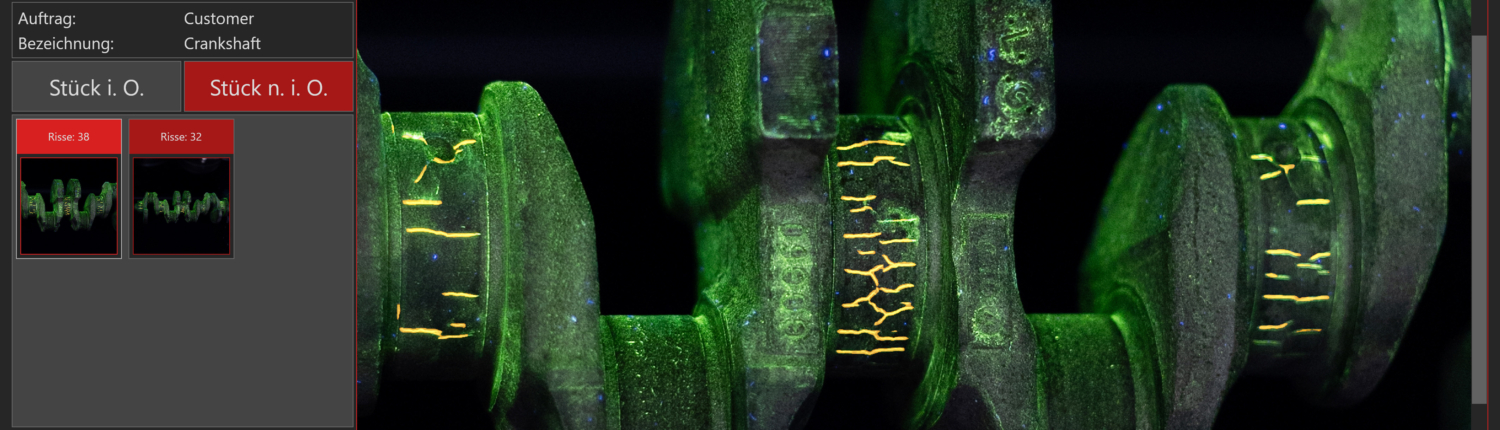

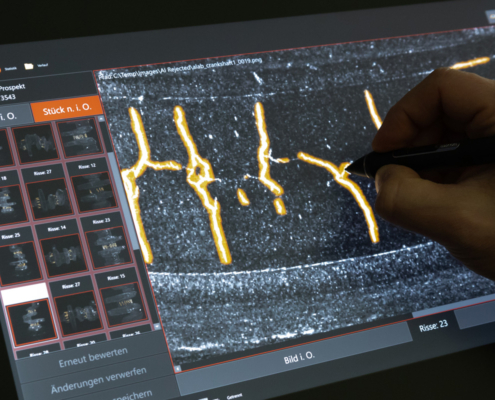

CRACKVIEW AI enables automated detection of MT indications with the help of artificial intelligence

The CRACKVIEW AI system digitises magnetic particle testing. The surfaces of the test parts prepared with magnetic particle are photographed using industrial cameras. The images of the surfaces are then analysed by a neural network (artificial intelligence / AI) trained by KARL DEUTSCH. It carries out a semantic segmentation of the images and determines the shape, position and number of possible crack indications with the associated crack probability. Thus, the components can be sorted to OK / NOT OK without a human inspector having to view them. The system significantly reduces inspection costs and delivers consistent inspection quality 24/7, all year round. In addition, the individual test results of the components can be documented, archived and traced for the first time.

Key Facts

CRACKVIEW AI test station

- High-performance industrial PC with NVIDIA GPU

- Flexible multi-camera setup with UV-illumination complying with ISO 3059

- Motorised rotary plate with component fixture

- Automated image acquisition by PLC control

CRACKVIEW AI software

- Core of the CRACKVIEW AI system

- Interface between neural network, PLC and cameras

- Neural network for semantic segmentation

- 3 modes: Adjustment / Manual / Automatic

- Database for order/part-related test results

- Inspection statistics

Images

Versions

CRACKVIEW AI

(order no. under preparation)

Automated AI-based detection of MT indications

Further Information

Our comprehensive brochure:

Things to know and accessories: