Accessories for Ultrasonic Flaw Detectors

Adjusting Standard

The adjustment standard is a useful tool for the daily check of the gauge length adjustment of ultrasonic devices or for checking linearity and sensitivity. It is connected via a Lemo-1 connector like a monoelement probe and provides an echo sequence with at least 10 clearly separated and short ultrasonic pulses at a precise distance of 50 mm or 100 mm steel (cl = 5920 m/s).

- Adjusting Standard, 50 mm echo sequence

(order no.: 1842.001) - Adjusting Standard, 100 mm echo sequence

(order no.: 1842.002)

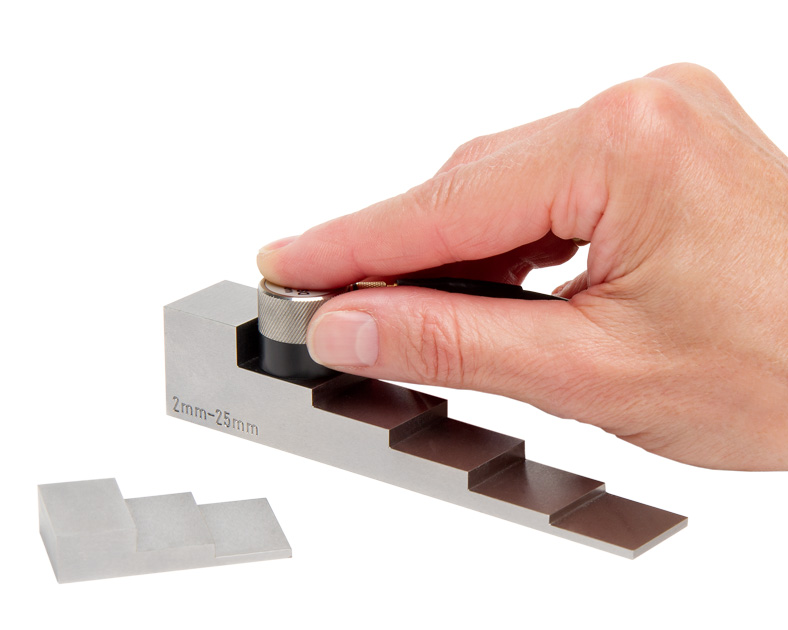

Step Wedge

A step wedge provides defined material paths with plane-parallel insonification and sound exit surfaces and is used for adjustment and check of the gauge during wall thickness measurement. KARL DEUTSCH’s product portfolio includes two step wedges, each with different steps and contact surfaces.

- Step Wedge 2 – 25 mm (order no.: 1713.001)

Graduations: 2, 4, 8, 12, 16, 25 mm +/- 0.05 mm

Contact area per step: 20 mm x 20 mm - Step Wedge 2 – 10 mm (order no.: 1713.002)

Graduations: 2, 5, 10 mm +/- 0.05 mm

Contact area per step: 15 mm x 25 mm

Calibration Block

The calibration blocks are manufactured according to the specifications in DIN-EN-ISO standards and are indispensable for adjusting and checking of ultrasonic testing equipment. In addition, a number of exercises can be solved to familiarize students with ultrasonic technology. The calibration blocks are supplied for protection in a sturdy wooden storage box or a leatherette bag.

- Calibration Block 1 according to DIN EN ISO 2400

(order no.: 1703.001) - Calibration Block 2 according to DIN EN ISO 7963

(order no.: 1702.001)

Further Information

Our comprehensive brochure: