ScanMaster Ultrasonic Spot Weld Testing Instruments

The ScanMaster spot weld inspection systems – UT/X, UT/MATE and UT/PRO – use algorithms proven over decades to evaluate ultrasonic signals generated during the inspection of resistance-welded spot joints. In contrast to destructive testing methods (tear tests, hammer and chisel) the test parts remain intact. In addition to the avoidance of scrap, ultrasonic testing offers the advantage that considerably more points can be inspected in much shorter periods of time. Automatic evaluation and archiving as well as statistical evaluations allow a quick feedback on the welding process.

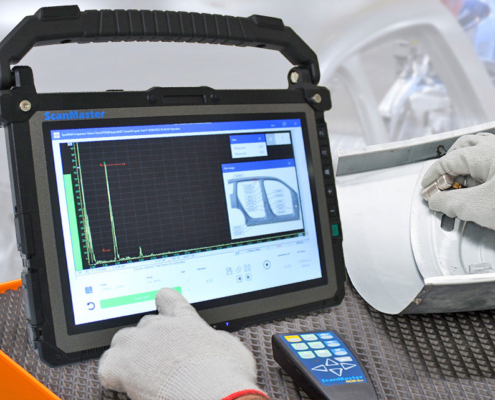

The UT/X represents a consistent further development of the conventional systems UT/MATE and UT/PRO. Based on the phased array technique, measured parameters such as lens diameter and welded area can be included in the result in addition to the previous evaluation methods. The system also provides a visual impression of the welding lens.