Phased Array testing at TMK-ARTROM

Wuppertal, Germany, October 19, 2020

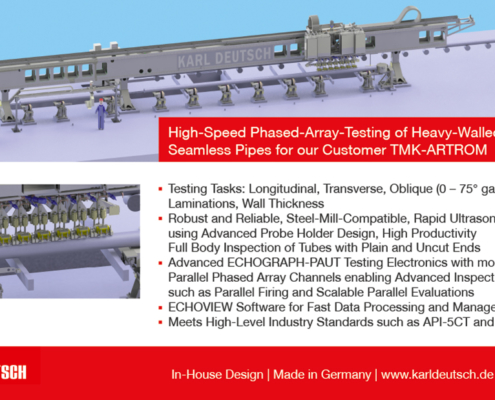

High-Speed Phasted Array Testing of Heavy-Walled Pipes

At our customer TMK-ARTROM, the robust and proven ECHOGRAPH-PAUT-RPTR ultrasonic rotary pipe inspection system is used for complete volume inspection. The sophisticated ECHOGRAPH-PAUT phased array electronics meets the most demanding requirements for volume and surface inspection of seamless tubes. Current and ambitious industry standards such as API-5CT/-5L are covered as well as the more demanding inspection requirements for complete detection of skew defects up to 75° in thick-walled tubes. A new probe holder design for fast coupling and advanced inspection modes such as parallel shots enable highest productivity.