KD-CHECK Systems: Dye Penetrant Testing System for Castings

Wuppertal, Germany, 28 March 2022

KD-CHECK Systems: Dye Penetrant Testing System for Castings

For the company METTEC GUSS Metallgießerei und Formenbau GmbH in Wels, Austria, a manual and modular dye penetrant testing system was implemented for small and medium-sized castings, which are tested using the red-white method. In addition to small series in baskets and racks, larger components can also be moved individually through the system and tested.

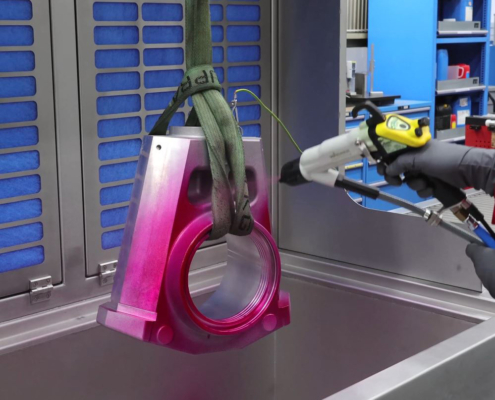

After the test parts have been washed and dried in the first stations, the penetrant is applied. Here, the customer may choose from various options: The penetrant station has an immersion tank, an electrostatic unit and a suction wall. This allows the inspector to choose whether he wants to apply the test agent by immersion, e.g. for baskets with many small components, or whether he prefers to apply it electrostatically for complex and structured castings. The use of spray cans is also possible without any problems.

After the penetration time, intermediate cleaning takes place. The wash water is circulated in activated carbon columns where it is freed from test agent residues.

This means that it can be used several times for intermediate cleaning, which not only saves costs but also preserves resources.

Before the developer is finally applied, the parts have to be dried. In addition to adjustable air baffles inside, the isolated unit also contains height-adjustable insert grids so that the inspector can adjust the optimal air flow for the respective component.

At the subsequent station the developer is applied with spray cans. Afterwards, the inspection takes place – either with the parts hanging on the crane or, in the case of small parts, on the inspection table. Finally, the test parts are sorted (GO and NO GO) and made available for further processing.