ECHOMETER 1076 K: Indirect Measurement

Wuppertal, Germany, 07 March 2022

ECHOMETER 1076 K: Indirect Measurement

If we want to measure a length, we can read it directly from a ruler or tape measure. Likewise, we can measure electrical voltage and current directly.

However, we often have to measure quantities indirectly. For example, we measure temperature via the expansion of liquids or speed via the number of wheel revolutions per time.

By combining different direct measurement methods, we can record measurands for which we do not know any direct measurement method. One of these measurands is the concentration of the components of liquids. Changes in concentration are often accompanied by a change in density, which can be measured, for example, via the refraction of light or the buoyancy of a floating body. The sound velocity also changes as a function of concentration. The precise measurement of sound travel times is the task for which KARL DEUTSCH developed its ECHOMETER.

The ECHOMETER 1076 K successfully complies with this task! The device comes with a special ultrasonic probe so that you can measure the sound travel time for a defined sound path and thus determine the sound velocity of a liquid. With the high resolution of the transit time, it is possible to display the sound velocity of liquids with 2 digits after the decimal point which corresponds to an accuracy of 0.001 %. This high resolution is necessary for concentration measurement, as the sound velocity often changes only slightly when there are changes in the concentration. Therefore, the exact knowledge of the actual free path distance is crucial and must also be known accurately to 0.001 %.

For the probe shown in the picture (above) with a path length of 20 mm, this corresponds to 0.2 μm, indicating that the high measurement accuracy as an absolute value is only possible with precise calibration. The temperature of the solution is also highly relevant, as it also influences the sound velocity. In addition to the sound velocity, the temperature must also be recorded or kept constant. A digital thermometer is included in the ECHOMETER 1076 K scope of delivery to check the temperature.

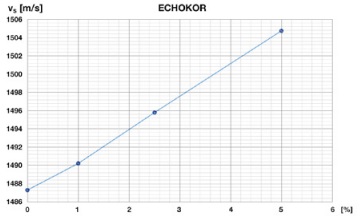

The graph (left) shows the correlation between concentration and sound velocity for the corrosion protection agent ECHOKOR in ultrapure water at 19 °C. It is now easy to check whether the concentration of a dilution is within the recommended range of 1.0 to 2.5 % by measuring whether the sound velocity is between 1490 m/s and 1496 m/s.