ECHOGRAPH Ultrasonic Probes: Optimised Durability

Wuppertal, Germany, December 21, 2020

ECHOGRAPH Ultrasonic Probes: Optimised Durability

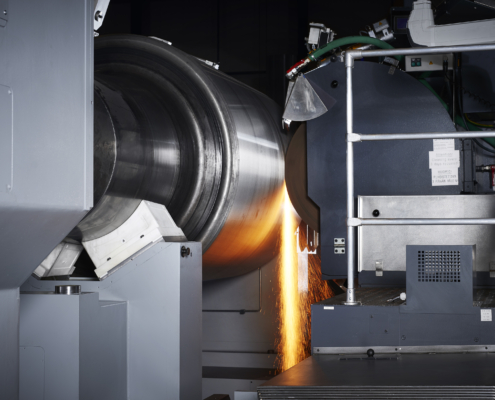

The companies of the HerkulesGroup are regarded worldwide as the definite experts for precise and efficient machining of large workpieces. Whether grinding, texturing, turning, milling or drilling – as specialists for large machine tools, the independent companies of the owner-managed group offer versatile and customised solutions.

The name Herkules is synonymous worldwide with pioneering technology in the high-precision machining of rollers and other workpieces. With over 100 years of history, the family-owned company stands for tradition paired with innovation and constant optimisation of its machine tools. Regarding the probes used to measure the quality of rollers and their machining, the HerkulesGroup has a long co-working experience with the company KARL DEUTSCH in Wuppertal. In 2020, the durability of the probes used was further optimised in a joint development project. In cooperation with the KARL DEUTSCH probes department, a special sensor alternative was developed that increases the service life and at the same time precisely meets the test task.

The previously used sensor was optimised for the requirement of achieving a very high sensitivity with a short pulse shape at the same time. As it is generally the case, a thin protective layer with the thickness of the best acoustic adaptation was used. To improve the service life, a protective coating

resin more resistant to coupling agent attack was used and its thickness was increased. This way, it was possible to develop a sensor with only slightly reduced sensitivity and a somewhat longer pulse length, which, however, has a very great advantage for the HerkulesGroup as a user in terms of service life. Development support for the solution of customer requirements is a basic principle of the KARL DEUTSCH company. The high level of reliability in bringing feasible product optimisations to production maturity in a timely manner is an important reason why the HerkulesGroup has been working successfully with KARL DEUTSCH for many years.