ECHOGRAPH STPS PAUT: Phased Array Bar Testing System

Wuppertal, Germany, 03 January 2022

ECHOGRAPH STPS PAUT: Phased Array Bar Testing System

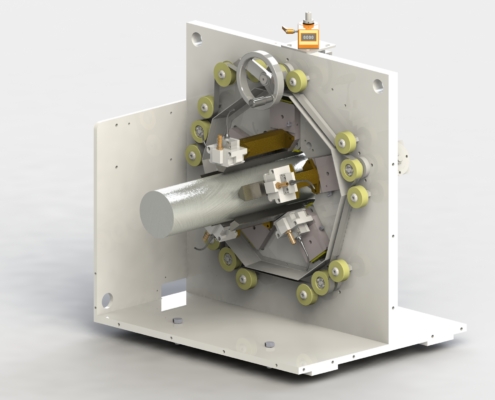

The ECHOGRAPH STPS PAUT Bar Testing System features a high testing speed of up to 2 m/s and an easy adjustment of the probe carriers.

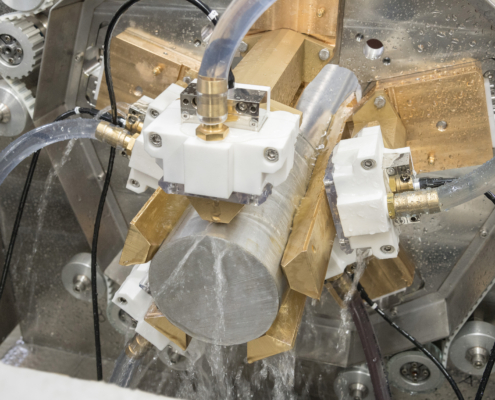

The detection of internal defects is done by straight beam shots, while defects close to the surface are detected with angle shots. The ultrasound is coupled via guided water jets (squirters) and enables inspection conditions that are similar to immersion testing with short uninspected ends.

Non-contact coupling ensures low probe wear, even when testing black bars. Five phased array probes, equally spaced (72°) around the bar circumference, are used for defect detection. The probes generate sector scans with up to 20 shots. In total, up to 120 parallel inspection channels are used. The sound

fields of the five phased array probes provide multiple overlap with 100 % coverage of the entire cross-section. The probe carriers are mechanically protected by skids, which also ensure stable coupling and test conditions by guiding the probe carriers along the bar surface.

Unavoidable mechanical straightness tolerances of the bars are compensated by the spring-loaded suspension of the probe carriers.

The test mechanism is mounted on a height-adjustable test table. The horizontal sliding device on the test table is used to move the test mechanics between the test position (in-line) and the calibration position (off-line). In the off-line position, calibration and service work can be carried out without disturbing the ongoing production.

The specimens are fed in via centric rollerdrives. After examination, the tested bars are usually sorted automatically (GO and NO GO). In most cases, the necessary mechanical conveyors are provided by the customer to ensure smooth integration into the production line.