ECHOGRAPH 1095: Matrix Memory

Wuppertal, Germany, 31 January 2022

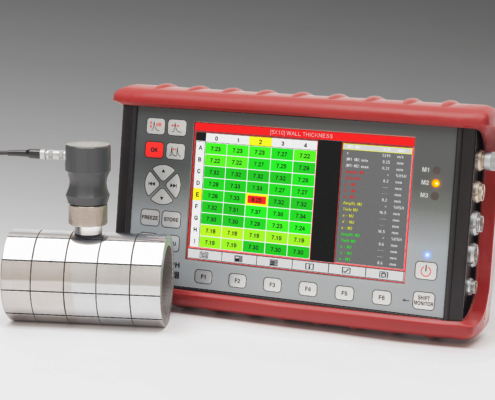

ECHOGRAPH 1095: Matrix Memory

In combination with the wall thickness measurement, the matrix memory is an ideal supplement for a corrosion test.

The matrix memory can also display asymmetrical measurement series, e.g. different levels with different measuring positions. The individual measuring points are evaluated in colour and a comprehensive evaluation, such as standard deviation, mean value, maximum and minimum value, are visible directly on the ECHOGRAPH 1095 screen. Optionally, each A-scan of the measurement series can be saved and faulty measurements can be overwritten or deleted. Another advantage is the possibility to save templates to repeat standard measurements easily and quickly. In addition to wall thicknesses, amplitudes and transit times of all three gates can be recorded.

Changing the evaluation, e.g. to amplitude evaluation, is possible even after the measurement series has been completed. The matrix memory can be used as a helpful supplement wherever a fast evaluation of measurement series with runtime, amplitude or wall thickness is required.