ECHOGRAPH 1095: DGS Testing with TR Probes

Wuppertal, Germany, 24 January 2022

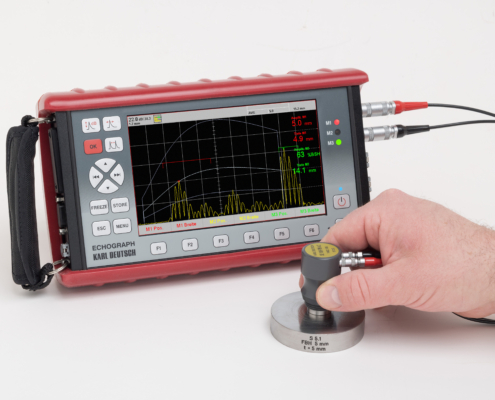

ECHOGRAPH 1095: DGS Testing with TR Probes

The ECHOGRAPH 1095 offers a variety of advanced testing options such as the DGS method with TR probes to determine equivalent reflector sizes.

In addition to the generally valid DGS diagrams for straight and angle beam probes, the ECHOGRAPH 1095 also provides special DGS diagrams for a defect size determination with TR probes. A combination with other test methods, such as backwall echo drop, is possible. The very fast gain change during backwall echo drop enables DGS flaw size determination up to 0.1 mm in front of the backwall echo. Age-related wear of the probe wedge can be compensated for by a wizard-supported delay line adjustment. Pre-adjusted probes can be stored with their serial number in a probe database.

By selecting a probe from the database, the data determined by the last delay line adjustment is automatically reused.