DEUTROMAT: Chain Conveyor of the Latest Generation

Wuppertal, Germany, 24 March 2022

DEUTROMAT: Chain Conveyor of the Latest Generation

An impressive DEUTROMAT chain conveyor was recently developed and built at KARL DEUTSCH for the Dutch foundry NEFIT INDUSTRIAL.

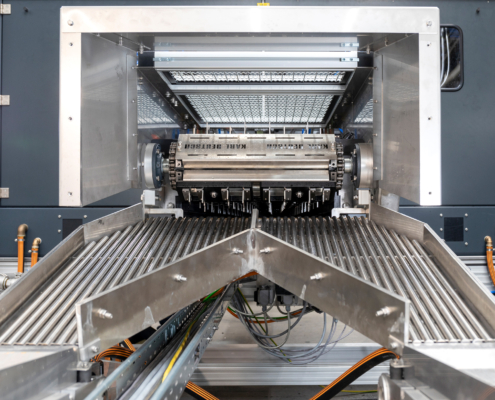

This modern system enables the customer to perform combined fluorescent magnetic particle testing on six castings simultaneously in one magnetisation cycle with a throughput of one component every two seconds (incl. transport time within the magnetisation station). The testing system contains three enhanced magnetising units of the UMT type.

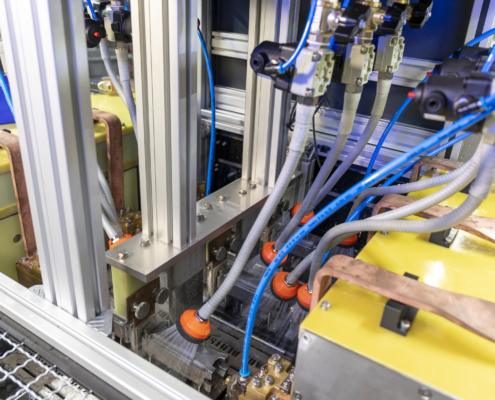

The machine is designed for many different types of components with varying geometries. The components of the respective type are inserted at the machine infeed into the appropriate (quickly exchangeable) workpiece holders. Each magnetising unit is equipped with special swivelling, laminated attachment yokes for fork-shaped parts and devices for one-sided internal flushing of hollow parts. The enhanced magnetic coils built into each unit ensure sufficient magnetisation of long workpieces. The many individual component-specific magnetisation parameters (recipes) are conveniently recorded, stored and activated as required using the DEUTROFLUX MEMORY PLC software.

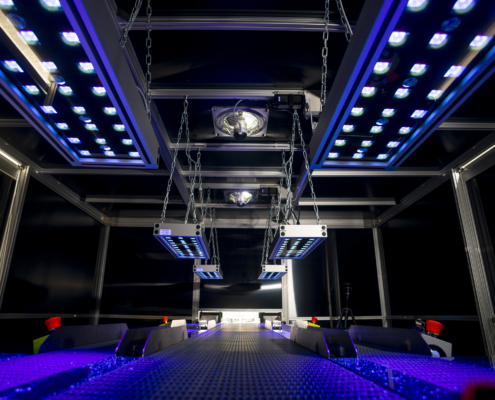

Upon customer request, we have built long conveyor belts at the outlet of the magnetisation unit so the components enter the darkening cabin as dry as possible (without the light-reflecting water film), which reduces the effort of the employees when executing the visual inspection and thus makes the inspection more reliable overall.

To fully utilise the high potential of this system, eight employees are needed: Two for loading the workpieces, another six for the visual inspection of the parts in an appropriately large and ventilated darkening cabin. The six operator positions are equipped with large-area UV-LED lamps from KARL DEUTSCH. Depending on the number of employees available at the infeed and in the darkening booth, the speed of the component transport can be adjusted accordingly with a push of a button. Defect-free components are placed on a centrally positioned conveyor belt by the employees in the darkening booth and then pass through the demagnetisation process by means of a suitable ESV coil. The system has been in continuous operation at NEFIT INDUSTRIAL for several months to their complete satisfaction.