DEUTROFLUX: Crack Testing on Components for High-Efficiency Combustion Engines

Wuppertal, Germany, April 5, 2020

DEUTROFLUX: Crack Testing on Components for High-Efficiency Combustion Engines

Progress and innovation in electro-mobility have given the market for combustion engines a good shake-up. In a global comparison, however, the combustion engine is still indispensable. There have also been many innovations in the technology of internal combustion engines in recent years. In order to increase the amount of oxygen in the combustion chamber, the fresh gas pressures have been increased more and more with the aid of turbocharging. By increasing the fuel injection pressures, it became possible to significantly reduce the amount of fuel needed. In particular, to reduce the friction values, the weights of components such as pistons, crankshafts and connecting rods were considerably lowered. Combustion chamber sizes and fuel consumption have almost halved in recent years, leading to high-compression engines.

Due to technical development of the engines, the quality demands on the components have raised considerably. All components of a modern combustion engine must be able to withstand higher loads, and this to a much greater extent than it was the case just a few years ago – while maintaining the longest possible running and operating times.

Faulty components can lead to significant damage in the engine compartment. In addition to the material damage, however, the associated immaterial damage in the form of loss of image, for example, may also not be inconsiderable. It is therefore all the more important to detect and sort out faulty components at an early stage in the production process. With its versatile inspection systems, KARL DEUTSCH offers the right solution for every test part family.

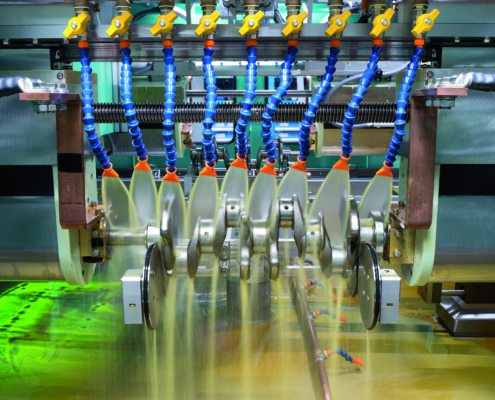

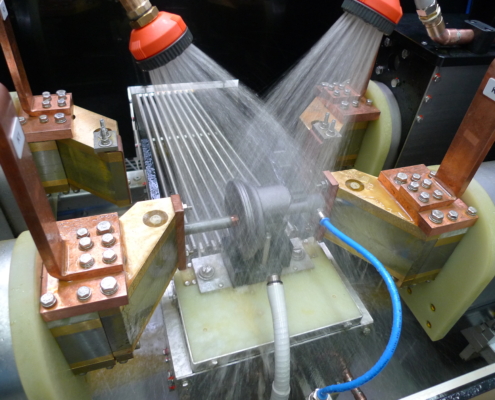

An essential and at the same time highly stressed part of the engine mechanics is the crankshaft. It is the central link in the engine block and converts the oscillating motion of the pistons into a circular motion. The main loads on a crankshaft occur in the area of the main bearings and the bearings of the connecting rod. Therefore, a major focus of its material testing is on the mentioned bearing surfaces and the connecting shaft areas. This testing task is optimally solved by test benches of the DEUTROFLUX UWS series with combined magnetisation and a moving coil.

This also applies to the latest project for a well-known Indian manufacturer of crankshafts for three-cylinder engines. In order to meet the cycle time specifications, the machine was designed as a double system and provides two separate magnetising stations. The completed system is currently on its way to the customer in India and will be commissioned in the next few weeks. On site, the system will be operated in the interlinking of the fully automated production line. Feeding is carried out by a robot system with double gripper.

A careful interface coordination before delivery was important for this project. Communication with the higher-level control system had already been tested in detail at the Wuppertal plant, so commissioning at the customer‘s site is carried out independently and without the support of KARL DEUTSCH service engineers. Thus, the business trip in Corona times can be avoided. Thanks to our global network of sales partners, we are able to provide expert support worldwide. In this case, the initial training is provided by NDT TECHNOLOGIES based in Mumbai.